original

Process Specification

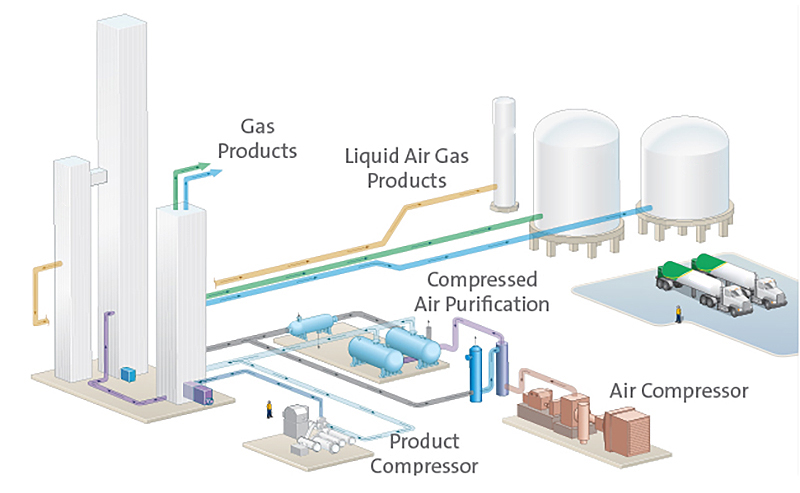

This set of equipment using molecular sieve adsorption and turbine expansion mechanism is cold, and products and produce argon without hydrogen compression in the full low pressure process, this device includes: air filtration system, compressed air system, air precooling system, molecular sieve purification system, gas liquid distillation system, turbine expansion units, product storage, instrument control system, electronic control system.

Raw materials of air in the air filter to remove dust and other mechanical impurities, into the air turbine compressor, air compressor to the required pressure, and then enter the air cooling tower and water to heat exchange and then enter the alternate use of two molecular sieve adsorber, here the impurities such as moisture in the air, CO2, C2H2 by molecular sieve adsorption.

After molecular sieve adsorption, raw air is supercharged by the supercharger. After cooling by the cooler, it enters into the main heat exchanger. Part of the gas is extracted from the middle part of the main heat exchanger and enters into the expander. After the other air enters the main heat exchanger, it is cooled to saturation by reflux gas and enters the lower tower with a small amount of liquid. Air after the preliminary distillation tower, the tower for about 36 ~ 38% of oxygen-enriched air, treating the liquid nitrogen, liquid air and liquid nitrogen by waste nitrogen and nitrogen on the supercooler after cold throttling into the tower, the scripture after further distillation tower, on the bottom for the purity of 99.6% oxygen, the oxygen out of the cold box, after the main heat exchanger after heat into oxygen compressor drive users after pressure to 3.0 MPa. The liquid oxygen is taken from the bottom of the upper tower and sent to the liquid oxygen tank. Nitrogen ≤10PPmO2 is obtained from the top of the upper tower. After reheating by the cooler and the main heat exchanger, it comes out of the cold box and enters the nitrogen press to be pressurized to 2.5mpa before being sent to the user. The dirty nitrogen is extracted from the top of the upper tower, reheated through the cooler and the main heat exchanger, and then comes out of the cold box. After heating all the way into the regeneration heater, it is used as the molecular sieve regeneration gas. The other way is sent to the water cooling tower and the normal temperature water for heat exchange to recover the cooling amount and then empty out.

Drawn from the tower bottom argon fractions in crude argon column I to the bottom of the vapor rising from the top of crude argon column I pulled into the bottom of the crude argon column II, after the two tower distillation in crude argon column II at the top of the crude argon, most of the crude argon into crude argon column condenser, liquid was empty a condensed liquid back into the crude argon tower as a crude argon tower of reflux liquid. The liquid returned to the coarse argon tower II is pressurized by liquid argon pump and fed to the top of the coarse argon tower II. The liquid fraction after rectification in the crude argon tower I returns to the upper tower from the bottom, and a small part of the crude argon goes into the refined argon tower after the liquefier. After rectification in the refined argon tower, the required pure argon can be obtained at the bottom of the refined argon tower.

3D Diagram

Strong After-Sales Service Team

1. Feature:

1. 1 A professional after-sales service team ;

1. 2 Professional 24-hour service telephone ;

1. 3 Equipment quality 12 months warranty.

2. Virtue:

There are 10 after-sales service personnel for a long time, among which 5 professional after-sales personnel with passports are on standby in the company, and there is a professional project department to connect with customers.

3. Benefits:

It is very important for you to maintain the equipment after sale, we can let you have no worries.

4. Evidence

Acceptance report, passport, project department, 24 hours telephone service department.

Workshop Production

Internal Structure Of Equipment

User Distribution (Abroad)

| Russia | New Zealand | Saudi Arabia |

| Kazakhstan | India | Iraq |

| Uzbekistan | Bangladesh | Nigeria |

| Tajikistan | Thailand | Angola |

| Mongolia | Philippines | South Sudan |

| Nepal | North Korea | Equatorial Guinea |

| Bolivia | Myanmar | Botswana |

Transportation

Installation