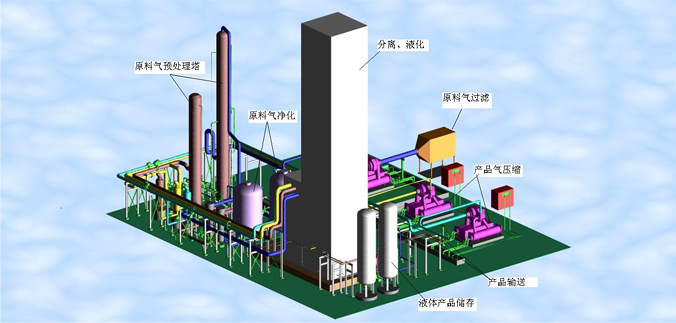

LNG liquefaction plant

Description

Natural gas can be directly converted or indirectly converted to produce high value-added chemical products. Because natural gas is a mixture of methane, it is an important raw material for the production of carbon-chemical products. The production of methanol, synthetic ammonia and other products is simpler than that of petroleum or coal as raw materials, and the operation is convenient and the product quality is high.

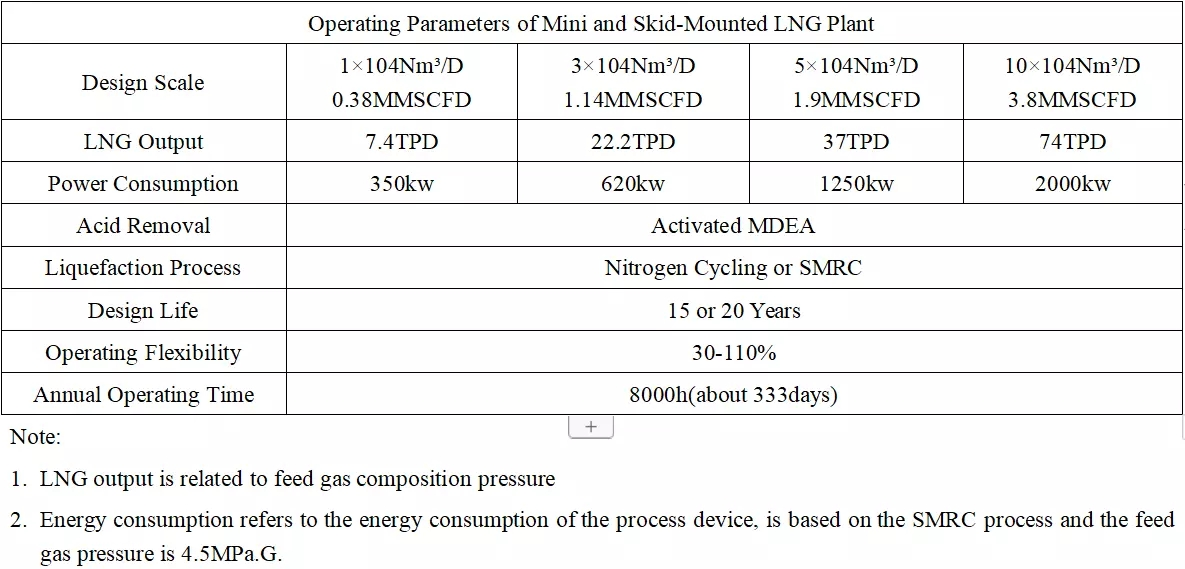

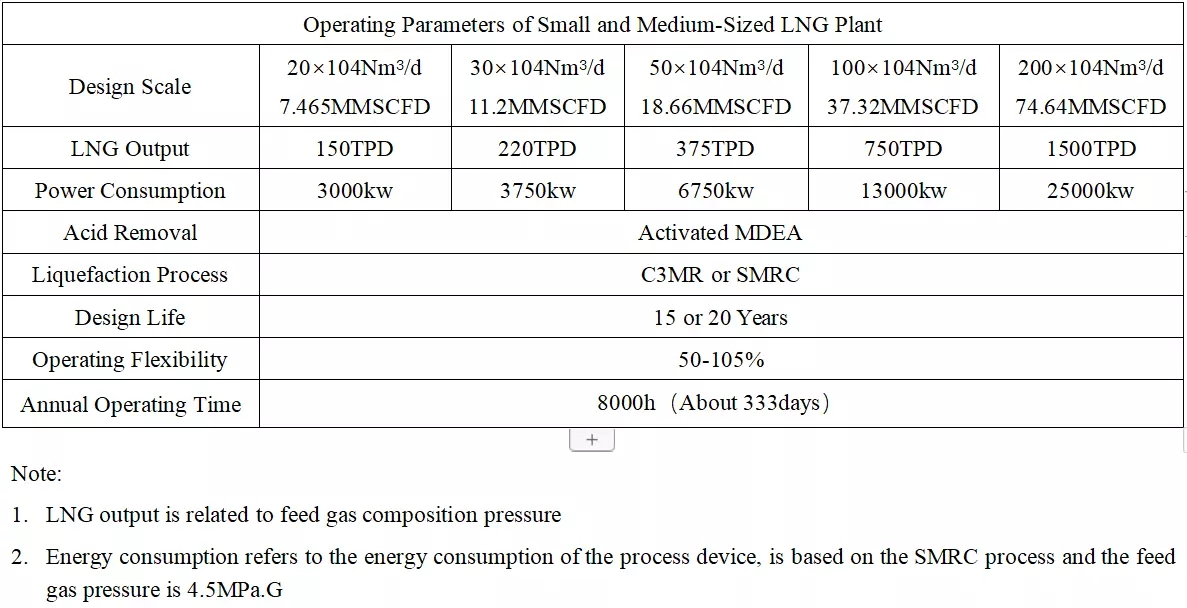

Specification

Associated petroleum gas (APG), or associated gas, is a form of natural gas which is found with deposits of petroleum, either dissolved in the oil or as a free "gas cap" above the oil in the reservoir. The gas can be utilized in a number of ways after processing: sold and included in the natural-gas distribution networks, used for on-site electricity generation with engines or turbines, reinjected for secondary recovery and used in enhanced oil recovery, converted from gas to liquids producing synthetic fuels, or used as feedstock for the petrochemical industry.

Like crude oil, APG is both a primary energy resource and a primary commodity that enables much of the modern world economy. Statistics from the International Energy Agency show that the natural-gas supplies steadily increased during 1990-2017 to meet the demands of expanding global population and consumerism. APG is nevertheless a finite fossil resource, and the crossing of planetary boundaries could impose earlier limits on its value and usefulness.

Following extraction, petroleum companies prefer to transport both crude oil and APG to their respective refiners for processing and distribution to consumers. Most modern wells are planned to include gas pipeline transport, but some oil wells are drilled only to get the more lucrative oil, in which case the options are to locally use, process, or dispose of the APG. A traditional local use is to re-inject the gas for storage, and to re-pressurize the well to extend the oil production lifetime. On-site processing with various mobile systems also exist for producing natural gas liquids (NGL), compressed natural gas (CNG), liquified natural gas (LNG), and gas to liquids (GTL) fuels that can be transported by truck or ship. Electricity generation from on-site microturbines and engines is also compatible with minimally processed APG.

Founded in 2017,OR has established a solid reputation in the Chinese Gas Industry by providing skid-mounted process solutions. We offer skid-mounted solutions optimized for each specific project, covering the following applications: Air Separation Plant/Unit, Gas Processing & Purification Unit, LNG Plant, LNG/ CNG Refueling Station, NGL Recovery Unit, Flare Gas Recovery Unit, Coke Oven Gas Purification & Separation Unit, Hydrogen Refueling Unit and Biological Fermentation Unit, etc. We can deliver skid-mounted solutions customized to meet client’s challenges and requirements (including adverse weather conditions, transportation and plot area limitations, etc).